Gamers and auto workers both are left in the lurch by one key component they can’t get. Rep. Haley Stevens (D-Livonia) wants to make sure that crisis doesn’t happen again.

LIVONIA, Mich.—An oddity in the cultural zeitgeist of 2021 is the global obsessive hunt for hard-to-obtain video game consoles. Headlines showcase the remarkable scarcity of the PlayStation 5 and the Xbox Series X, and the lengths players have gone to to get their hands on the near-mythical technology.

Even Newsweek is posting regular restock updates. But the situation causing that shortage is much farther reaching than video game consoles. It’s hitting automakers in Michigan.

A Supply Crisis on an Open World Scale

The reason Sony and Microsoft are struggling to keep their video game systems on the shelves is a global shortage in a very specific component used in electronics: semiconductors. Semiconductors are in most of the devices we use in daily life. From phones to refrigerators, from televisions to washing machines, the tiny tools are all around us all the time.

The shortage has even had consequences for national security, with the Department of Defense unable to acquire the technology it needs.

At the start of the pandemic, the factories making semiconductors shut down to put coronavirus safety measures in place. This put the manufacturers slightly behind their tight production schedules, and though they quickly got back on track, they emerged into a storm of demand that they weren’t ready for.

How Pausing Led to a Game Over

The pandemic made workers who could work remote shift to remote work meaning laptop and desktop computers were purchased and upgraded, the major video game platforms were coming out with new systems, 5G technology spiked demand for new mobile phones, and most crucially for Michigan, the automotive industry has become increasingly reliant on onboard computers.

SEE ALSO: Trump’s Trade Policy Was Hurting Michigan Businesses Long Before Coronavirus

Add to that a fire. In March, major Japanese semiconductor manufacturer Renesas had a blaze sweep through a clean room of their most advanced plant. Because semiconductors are so tiny and sensitive, they need to be manufactured in strictly controlled environments. Losing that would normally be a small hit to Renesas, but with the global shortage, it’s other plants can’t pick up the slack.

Oh, and the global shipping crisis caused by the Ever Given getting stuck in the Suez Canal.

All this compounded to create a situation that isn’t just hurting video game companies—it’s crippling the global economy at a time when a pandemic has already left the world in a recession.

A Semiconductor Shortage Upended the Strategy Guide

That supply chains are critical isn’t a new realization by any means. While prices for technology might see a rise from the semiconductor shortage, similar situations around steel and aluminum are still recent memories. What the semiconductor shortage has taught us isn’t the dangers of a breakdown, but rather the scale a breakdown can have.

Infrastructure is the umbrella term for systems that are essential to a society. This is seen physically in roads, bridges, buildings, and transportation. But equally, it exists in a less visual form. For instance, society as it exists today can’t operate without high-speed internet connections, satellites, or utilities like electricity and waste collection.

And supply chains are essential to every one of those things. Without reliable access to steel and concrete, bridges can’t be built. Without reliable access to aluminum, satellites and airplanes couldn’t help our global transportation and communication, and we see now without semiconductors we can’t have high-speed internet or refrigeration to keep vaccines from spoiling before they’re used.

The pandemic provided numerous examples of what happens when supply chains break at terrible moments, as well. Early on, things needed to treat the virus from ventilators to masks were scarce, toilet paper was a rare commodity, and even the vaccine faced supply chain issues.

Leveling Up Our Supply Chain Skills

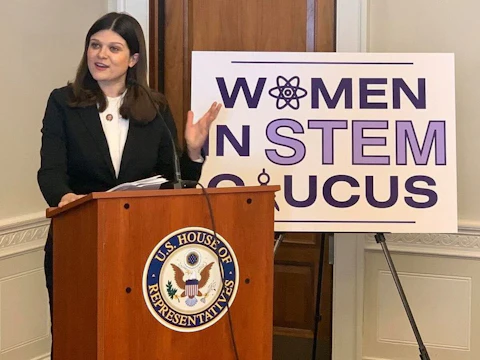

Representative Haley Stevens (D-Livonia) laid out the extent of the situation when introducing legislation to create a task force to look at supply chain failures.

“Future national security, public health, and other crises necessitate a resilient national economy,” she explained. “Supply chain interruptions at the beginning of the pandemic left healthcare providers and first responders across the country without essential, life-saving medical equipment.”

Of course, that isn’t to minimize the efforts manufacturers undertook, especially in Michigan, to produce that equipment. Ford’s Rawsonville plant in Ypsilanti converted entirely to producing ventilators, for instance.

“Michigan manufacturers stepped up and met the industrial call to action—switching gears and manufacturing essential personal protective equipment, ventilators, and medical devices,” Stevens pointed out.

But that isn’t a real fix for the problem. Much like with more physical infrastructure projects, what happened with automakers making ventilators was addressing a failure of a system after it had already collapsed rather than ensuring it wouldn’t. And had a robust supply chain existed for these various essential tools for saving lives existed before the pandemic, the last year would have run more smoothly and been measurably less tragic. This is especially true in the case of vaccine distribution.

RELATED: ‘It Opened the World to Us’: Broadband Infrastructure Can Transform Rural Michigan Life

That perspective is shared by President Joe Biden, who has included efforts to firm up the supply chains we depend on both personally and professionally as part of his American Jobs Plan, itself part of his broader infrastructure modernization package. His plan would provide financing assistance to help manufacturers closer to home produce things like semiconductors or ventilators.

“Doing nothing is not an option.,” Biden told auto workers in Dearborn in May. “It was the Defense Department and NASA that got the modern semiconductor industry on its feet decades ago. We started it, your tax dollars. Our own Department of Energy pioneered and transformed the battery industry while [President Barack Obama] and I were in office. Through the Recovery Act grants and loans, battery prices dropped 80% because we were looking forward. We need that same mindset today.”

And that in combination with Stevens’ plan to study ways to prevent these failures in the long term would put both the United States and the world in a stronger position when the next supply crisis hits.